We all know that changing our T5 bulbs regularly is important, but seriously not many of us really stay that rigorously on top of the bulb changing schedule. BulkReefSupply, as part of their incredible BRSTV series, did an investigation into how true the generally accepted notion “change your lamps every 12 months” really is.

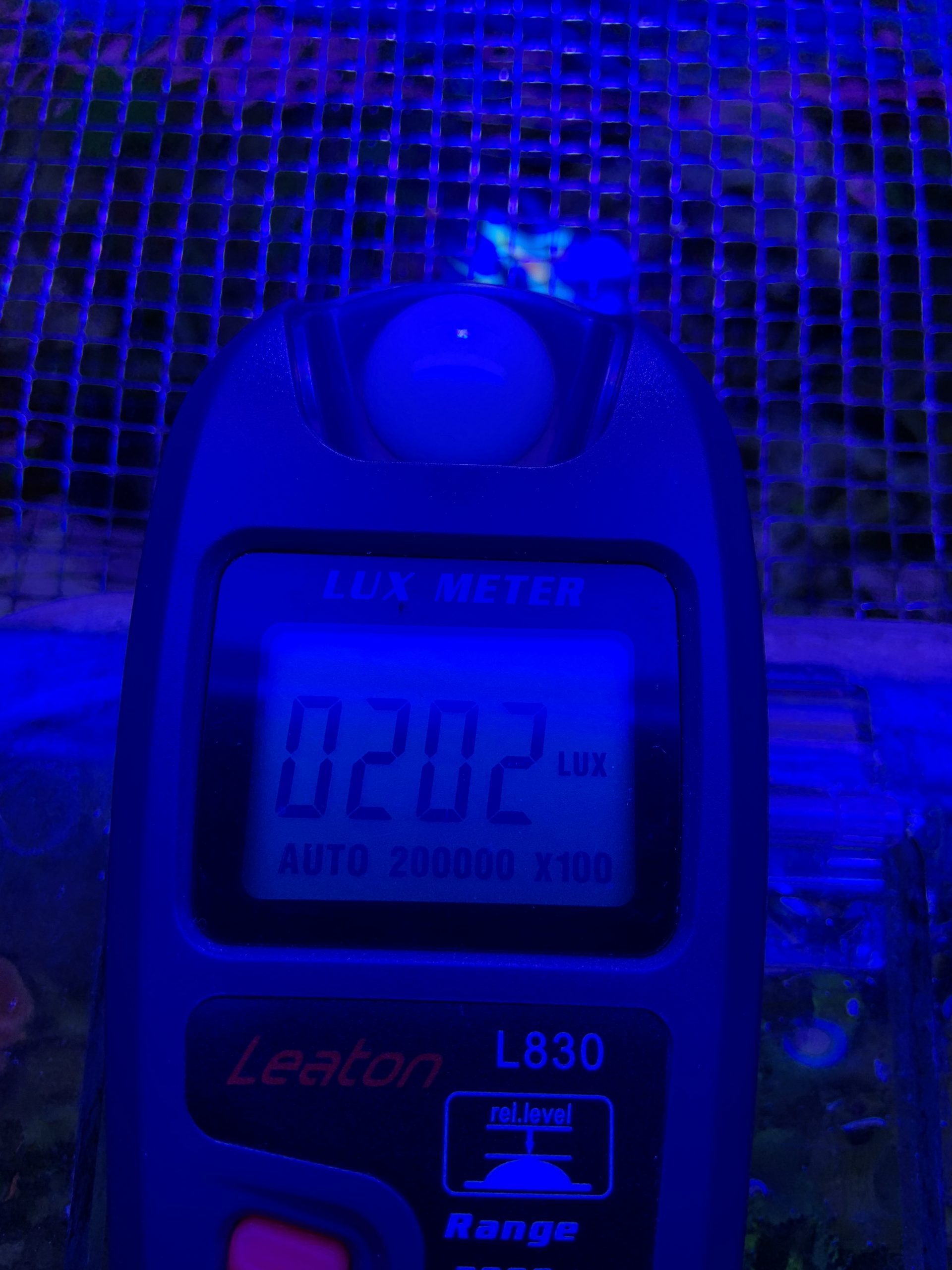

It finally dawned on me about 2 months ago that I couldn’t remember the last time I changed my T5s. My corals have been growing well, so I just let it be. One of the BRC club members brought up the subject of estimating PAR using a cheap lux meter. It reminded me, I HAVE A LUX METER! Wonder where my levels are….

Turns out they were lower than what I expected, but just how low? I ordered four new lamps from BRS and set out to find out.

Color Combination

I suppose a lot of this comes down to your personal preference. Some people like really blue tanks up above 12k, some people like a more natural 6500k look. I’m somewhere in the middle. I don’t like looking into a bowl of windex, but I want those fluorescent pops of color. I use a combo that’s pretty typical, I think.

2 ATI Blue Plus

1 ATI Purple Plus

1 ATI Coral Plus

From there, I adjust my color using my LED fixture to fine tune.

Aged Like a Fine Wine

When you’re going to be dimming your T5’s it is always recommended that you “burn in” or age your bulbs by running them for 50-100 hours so the phosphors all evenly distribute in the tube. I don’t know of anything saying you have to do this if you don’t dim, but I like to follow the process anyway. I have a 2 lamp fixture I use for QT that is perfect for this. I just pop two lamps in and come back for them in 2 days.

Watch out for the bump!

In this hobby, as we all know, only bad things happen quickly. That goes just the same for lighting. T5 lamps lose quite a bit of output as they age (see the YouTube video at the top for some numbers) and simply swapping in all new lamps can make for a huge bump in PAR and shock your corals. I decided to swap out one lamp per week for 4 weeks and chart the changes. Here are my results:

Week 0: Old Lamps @ 19,700 lux

Week 1: Blue Plus @ 20,200 lux

Week 2: Blue Plus @ 20,800 lux

Week 3: Coral Plus @ 25,900 lux

Week 4: Purple Plus @ 26,000 lux

From start to finish, that’s a whopping 35.6% increase in lux. Think your corals won’t notice a sudden jump that big? Trust me, they will!

Going Forward

Based on my own results and those from the BRS Investigation, I’m going to start swapping out on an 18 month cycle. I think that’s a good balance of lamp cost and lamp life. I don’t want to drop 35% again, but a 10-15% drop I can deal with.

Happy reefing!